Thermo Panel 4T

The Modular One

For decades, modular ceilings with visible grid constructions have determined the appearance of acoustically effective suspended ceilings.

We have based the development of our Thermo Panel 4T on these basic ideas of simplicity of construction, sound absorption and almost any access to suspended ceilings.

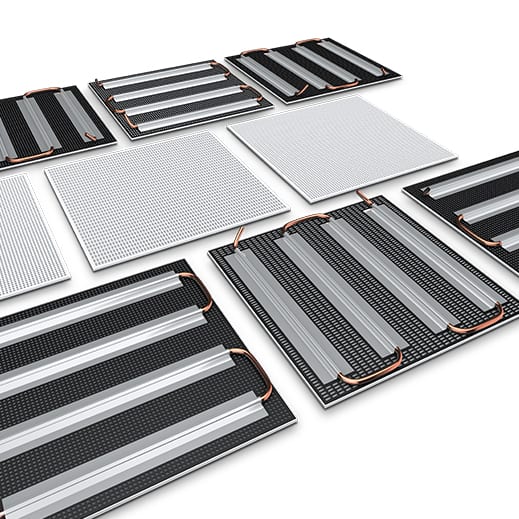

We deliver 6.5 mm thick, surface-ready plasterboard tiles, which are activated with a rear surface heat exchanger, to the construction project. The Thermo Panel 4T has four rows of tubes, due to the flat aluminium plate, which provides an enormous transverse conduction of the energy, in order to achieve an extraordinary cooling capacity.

This means that the holes in the heat exchanger, which run exactly parallel to the hole pattern of the plasterboard tile, are only slightly covered and the acoustic effectiveness is only marginally impaired.

The individual registers are connected to each other and the circles are finally connected to the manifold by means of flexible hoses covered in stainless steel and sealed against diffusion.

Our solution approach with a control loop distributor, in which one ball valve per beam is installed at the factory, replaces the otherwise necessary internal piping and thus ensures that the transfer point to the technical building equipment does not take place in the grey zone of the ceiling cavity, but is clearly and tangible defined.

In addition to water volumes and pressure losses in the zones and circles, our hydraulic designs also show the dimensions of the distributor and the maximum modules in a circle. The fine adjustment of the water volumes is carried out during commissioning on the fixed Taco-Setter of the distributor.